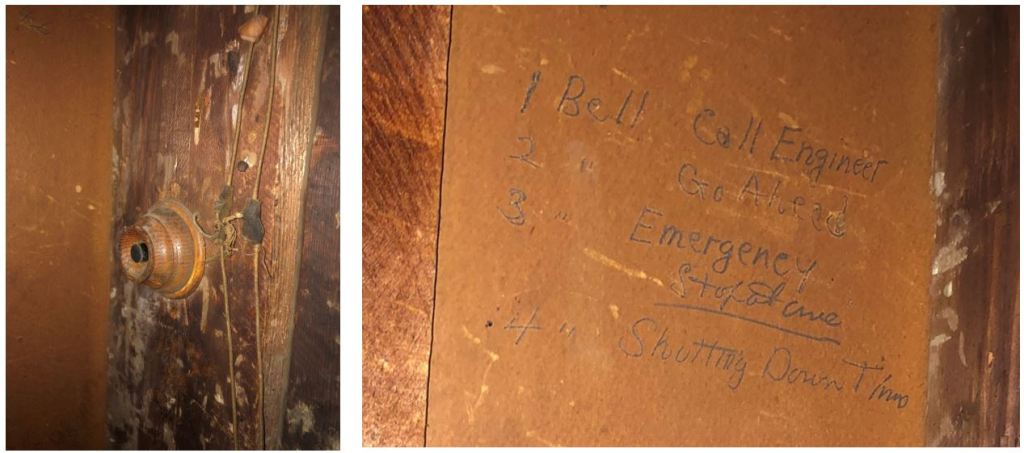

Over a decade ago, Mill researcher Tom Calderwood set out to photograph and identify as much of the Old Schwamb Mill’s contents as he could. Among his many interesting finds was a wooden “door bell” style button in the corner of the glue room.

Beside the bell were the words:

1 Bell Call Engineer

2 ” Go Ahead

3 ” Emergency Stop at once

4 ” Shutting Down Time

The button was apparently part of a system to signal the engineer in the basement of the Barn across Mill Lane. The Mill installed a coal boiler and steam engine in 1873 and employed an engineer until 1948, when inspectors determined it was no longer safe to operate the boiler for anything more than heating the Mill. Based on descriptions of the engineer’s work captured in the Mill’s accident reports, we know that the engineer filled the role of fireman as well, stoking the furnace with coal and wood shavings.

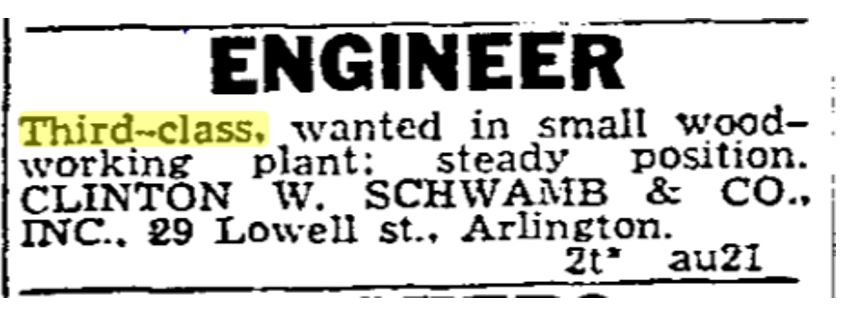

We know of 14 men employed as engineers at the Mill, all from the twentieth century. They were typically salaried, paid a set amount by the week, rather than paid an hourly rate like most of the employees. At the Clinton W. Schwamb Company, Inc., the engineer made somewhat less money per week than the top paid employees like the moulder or Louis Schwamb, the shop foreman, but significantly more than ordinary mill hands. Some men held the job for over a decade. Thomas F. Morris of Arlington was engineer from 1906 to 1916, when he was in his forties. John H. Hegh was hired in November 1924 and stayed until June 1938 when he left work at age 65.

For the last decade of steam power at the Mill, ten engineers held the job, often for as little as a few weeks, with Clinton or Louis Schwamb filling in as needed. One can imagine the difficulty of keeping an engineer to tend a boiler from the 1870s during World War II, when other good-paying jobs were available. It was an old system in cramped quarters – perhaps explaining the occasional burns and head bumps recorded in the accident reports.

The signaling system has two buttons, one in the glue room on the second floor and one on the first floor below mounted on a cabinet on the west wall. These buttons are connected in parallel to two cloth covered solid copper wires which once ran from the glue room across to a radiator pipe, then down to the Mill’s cellar. From the cellar, the wires passed through the brick foundation under the Mill’s west wall and apparently under what was then a dirt road, alongside an electrical conduit, now out of service. The wires enter the barn cellar through the building’s foundation near the northwest corner. From there, they run overhead to the cellar door, over which is an electric bell.

The bell, which still rings when connected to a 6-volt battery, bears the name Faraday in a much rusted, oval logo. Faraday made electric bells and other signals, specializing in reliable signals for use in engine rooms and places at risk of fire. The bell in the barn basement resembles ones produced in the period 1900s to the 1930s. It would have operated on battery power. Since the cloth-covered wires seem to run beside an old underground electrical conduit, it is possible that the wiring and the bell date from the installation of electricity at the Mill in 1919-20.

The bell, which still rings when connected to a 6-volt battery, bears the name Faraday in a much rusted, oval logo. Faraday made electric bells and other signals, specializing in reliable signals for use in engine rooms and places at risk of fire. The bell in the barn basement resembles ones produced in the period 1900s to the 1930s. It would have operated on battery power. Since the cloth-covered wires seem to run beside an old underground electrical conduit, it is possible that the wiring and the bell date from the installation of electricity at the Mill in 1919-20.

All that is needed to make this signaling system work again is to 1) add a battery to the existing circuit, 2) add wiring where some segments have been removed in the Mill and 3) run a new set of wires between the Mill and the Barn. While the original wires may remain under Mill Lane, no trace of them has been found in the ground alongside the Mill’s west wall where they would have entered the brick foundation. Running a new set of wires through the clay conduit housing the retired steam pipe between the Mill and Barn cellars would solve this problem, allowing the us to once again “call the engineer” during behind-the-scenes tours of the Barn and the old engine room.

How much would this cost? Such fun to discover their ingenuity!

LikeLike

That must have been a fun investigation! It was certainly fun to read. Do you know if the STOP emergency command was ever used?

LikeLike

No mention of any emergency stops in the directors minutes of the corporation. The signaling instructions are only written on the second floor, not on the first floor where a button also exists. Somehow it seems to me that the first floor with its many machines would be where one might call for an emergency shut down.

LikeLike